GENERAL INFORMATION

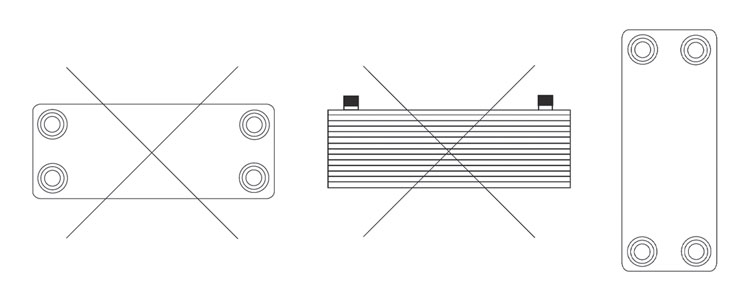

The BPHE should be mounted in the vertical position with the arrow on the front plate pointing upwards (Figure 1). Take care that neither vibrations nor pulsations can be transferred to the heat exchanger by installing, for example, mufflers or vibration absorbers.

In the case of larger connection diameters, we advise using an expanding device in the pipeline. Usually a rubber mounting strip can be used as buffer between the BPHE and the mounting clamp. Figure 2 shows several mounting suggestions.

Figure 1 – Advised Mounting Position

A. BPHE supported from the bottom

B. Sheet-metal bracket (Armaflex between the bracket and the BPHE)

C. Crossbar and bolts (Armaflex between the BPHE and the wall)

D. Stud bolts

CLEANING OF THE DANFOSS BPHES

Thanks to the normally very high degree of turbulence in BPHEs there is a self- cleaning effect in the channels. However, in some applications the fouling tendency can be very high, ego when using extremely hard water at high temperatures. In such cases it is always possible to clean the exchanger by circulating a cleaning liquid (CIP Cleaning In Place). Use a tank with weak acid, 5% phosphoric acid or, if the exchanger is frequently cleaned, 5% oxalic acid. Pump the cleaning liquid through the exchanger.

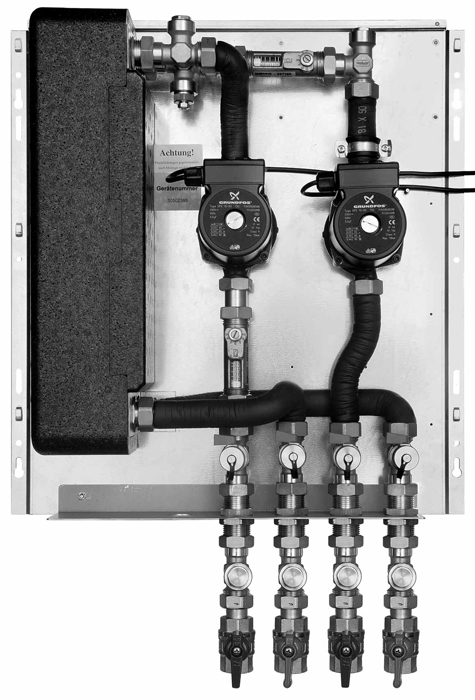

For tough installations we recommend factory-installed CIP connections/valves for easy maintenance.

For optimum cleaning, the cleaning solution flow rate should be a minimum of 1.5 times the normal now rate, preferably in a back-flush mode. After use, do not forget to rinse the heat exchanger carefully with clean water. A solution of 1-2% sodium hydroxide (NaOH) or sodium bicarbonate (NaHCO3) before the last rinse ensures that all acid is neutralized Clean at regular intervals.

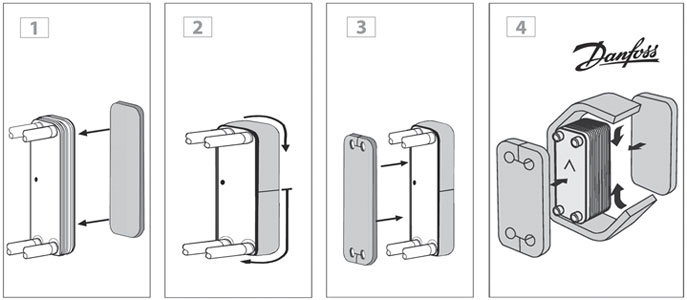

Danfoss Brazed Plate Heat Exchanger Insulation

INSULATION FOR REFRIGERANT APPLICATIONS

Danfoss BPHE insulation is recommended for evaporators, condensers or district heating applications, etc. For refrigeration, use extruded insulation sheets, e.g. Armaflex or equivalent which also can be supplied by Danfoss.

INSULATION FOR REFRIGERANT APPLICATIONS

For heating applications, various types of insulation boxes can be used. The working temperature range defines which insulation is recommended. Danfos can supply some of these insulation types as optional accessories

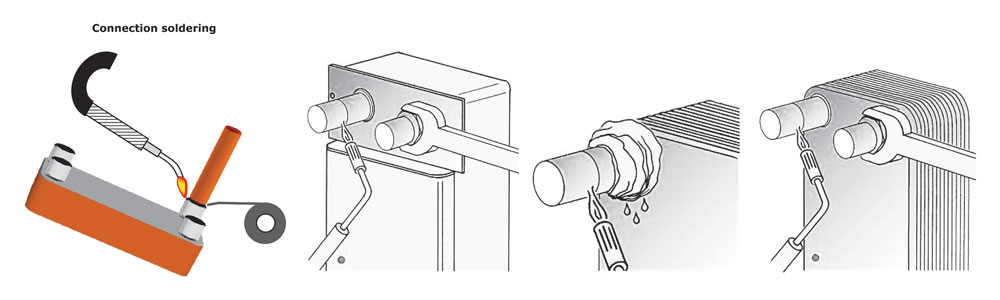

BRAZED PLATE HEAT EXCHANGERS SOLDERING

Use nitrogen in case of soldering. Carefully clean the surfaces that should be soldered. Push the pipe into the connection and solder with a 40-55% silver at a maximum of 700°. Do not point the flame against the top plate of the exchanger (1). Tie a weat rag around the connection to protect the exchanger against too intense heat (2). Insulated exchangers are protected by a aluminium plate (3).

Copyright 2009 – 2017 Techno Service Co. | All Rights Reserved | Powered by KaramiArt