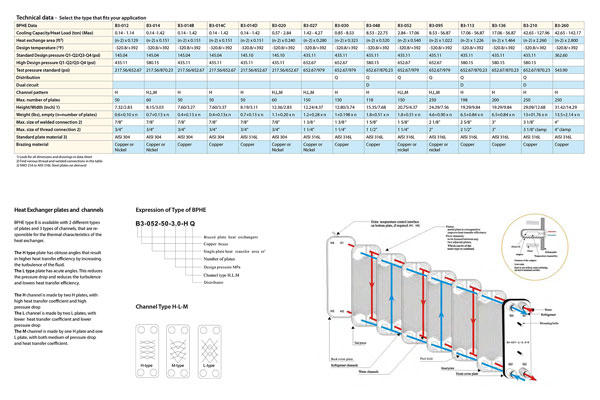

Danfoss Brazed Plate Heat Exchanger Technical Data

| BPHE Data | B3-012 | B3-014 | B3-014B | B3-014C | B3-014D |

|---|---|---|---|---|---|

| Cooling Capacity/Heat Load (ton) (Max) | 0.14 – 1.14 | 0.14 – 1.42 | 0.14 – 1.42 | 0.14 – 1.42 | 0.14 – 1.42 |

| Heat exchange area (ft2) | (n-2) x 0.129 | (n-2) x 0.151 | (n-2) x 0.151 | (n-2) x 0.151 | (n-2) x 0.151 |

| Design temperature (®F) | -320.8/+392 | -320.8/+392 | -320.8/+392 | -320.8/+392 | -320.8/+392 |

| Standard Design pressure Q1-Q2/Q3-Q4 (psi) | 145.04 | 145.04 | 145.04 | 145.04 | 145.10 |

| High Design pressure Q1-Q2/Q3-Q4 (psi) | 435.11 | 435.15 | 435.11 | 580.11 | 435.11 |

| Test pressure standard (psi) | 217.56/652.67 | 217.56/652.67 | 217.56/652.67 | 217.56/870.23 | 217.56/652.67 |

| Distribution | |||||

| Dual circuit | |||||

| Channel pattern | H | H | H | H,L,M | H |

| Max. number of plates | 50 | 50 | 50 | 60 | 50 |

| Height/Width (inch) 1) | 7.32/2.83 | 8.15/3.03 | 7.60/3.27 | 7.60/3.37 | 8.19/3.11 |

| Weight (lbs), empty (n=number of plates) | 0.4+0.10 x n | 0.4+0.13 x n | 0.4+0.13 x n | 0.7+0.13 x n | 0.7+0.13 x n |

| Max. size of welded connection 2) | 7/8″ | 7/8″ | 7/8″ | 7/8″ | 7/8″ |

| Max. size of thread connection 2) | 3/4″ | 3/4″ | 3/4″ | 3/4″ | 3/4″ |

| Standard plate material 3) | ANSI 304 | ANSI 304 | ANSI 304 | ANSI 304 | ANSI 316L |

| Brazing material | Copper or Nickel | Copper or Nickel | Copper | Copper | Copper |

| BPHE Data | B3-020 | B3-027 | B3-030 | B3-048 | B3-052 |

|---|---|---|---|---|---|

| Cooling Capacity/Heat Load (ton) (Max) | 0.57 – 2.84 | 1.42 – 4.27 | 0.85 – 8.53 | 8.53 – 22.75 | 2.84 – 17.06 |

| Heat exchange area (ft2) | (n-2) x 0.240 | (n-2) x 0.280 | (n-2) x 0.323 | (n-2) x 0.520 | (n-2) x 0.540 |

| Design temperature (®F) | -320.8/+392 | -320.8/+392 | -320.8/+392 | -320.8/+392 | -320.8/+392 |

| Standard Design pressure Q1-Q2/Q3-Q4 (psi) | 145.10 | 435.11 | 435.11 | 435.11 | 435.11 |

| High Design pressure Q1-Q2/Q3-Q4 (psi) | 435.11 | 652.67 | 652.67 | 580.15 | 652.67 |

| Test pressure standard (psi) | 217.56/652.67 | 652.67/979 | 652.67/979 | 652.67/870.23 | 652.67/979 |

| Distribution | Q | Q | Q | ||

| Dual circuit | D | ||||

| Channel pattern | H,L,M | H,L,M | H | H | H,L,M |

| Max. number of plates | 60 | 150 | 150 | 118 | 150 |

| Height/Width (inch) 1) | 12.36/2.83 | 12.24/4.37 | 12.80/3.74 | 15.35/7.68 | 20.75/4.37 |

| Weight (lbs), empty (n=number of plates) | 1.1+0.20 x n | 1.2+0.28 x n | 1+0.198 x n | 1.8+0.51 x n | 1.8+0.51 x n |

| Max. size of welded connection 2) | 7/8″ | 1 3/8″ | 1 3/8″ | 1 5/8″ | 1 5/8″ |

| Max. size of thread connection 2) | 3/4″ | 1 1/4″ | 1 1/4″ | 1 1/2″ | 1 1/4″ |

| Standard plate material 3) | ANSI 304 | ANSI 316L | ANSI 316L | ANSI 316L | ANSI 316L |

| Brazing material | Copper or Nickel | Copper or Nickel | Copper | Copper | Copper or Nickel |

| BPHE Data | B3-095 | B3-113 | B3-136 | B3-210 | B3-260 |

|---|---|---|---|---|---|

| Cooling Capacity/Heat Load (ton) (Max) | 8.53 – 56.87 | 17.06 – 56.87 | 17.06 – 56.87 | 42.56 – 127.96 | 42.56 – 142.17 |

| Heat exchange area (ft2) | (n-2) x 1.022 | (n-2) x 1.226 | (n-2) x 1.464 | (n-2) x 2.260 | (n-2) x 2.800 |

| Design temperature (®F) | -320.8/+392 | -320.8/+392 | -320.8/+392 | -320.8/+392 | -320.8/+392 |

| Standard Design pressure Q1-Q2/Q3-Q4 (psi) | 435.11 | 435.11 | 435.11 | 435.11 | 362.60 |

| High Design pressure Q1-Q2/Q3-Q4 (psi) | 652.67 | 580.15 | 580.15 | 580.15 | |

| Test pressure standard (psi) | 652.67/979 | 652.67/870.23 | 652.67/870.23 | 652.67/870.23 | 543.90 |

| Distribution | Q | Q | Q | ||

| Dual circuit | D | D | |||

| Channel pattern | H,L,M | H | H | H | H |

| Max. number of plates | 250 | 198 | 200 | 250 | 250 |

| Height/Width (inch) 1) | 24.29/7.56 | 19.29/9.84 | 19.29/9.84 | 29.09/12.68 | 31.42/14.29 |

| Weight (lbs), empty (n=number of plates) | 4.6+0.90 x n | 6.5+0.84 x n | 6.5+0.84 x n | 13+1.76 x n | 13.5+2.14 x n |

| Max. size of welded connection 2) | 2 1/8″ | 2 5/8″ | 3″ | 3 1/8″ | 4″ |

| Max. size of thread connection 2) | 2″ | 2 1/2″ | 3″ | 3 1/8″ clamp | 4″ clamp |

| Standard plate material 3) | ANSI 316L | ANSI 316L | ANSI 316L | ANSI 316L | ANSI 316L |

| Brazing material | Copper or Nickel | Copper | Copper | Copper | Copper |

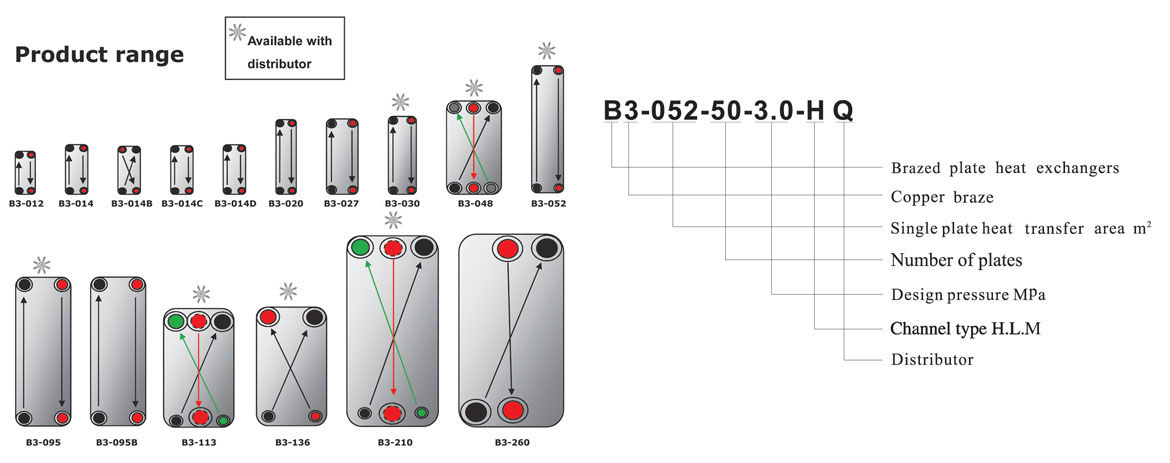

- Look for all dimesions and drawings in data sheet

- Find various thread and welded connections in the table

- SMO 254 or AISI 316L Steel plates on demand

Copyright 2009 – 2017 Techno Service Co. | All Rights Reserved | Powered by KaramiArt