MicroPlate Brazed Plate Heat Exchangers (new)

In air conditioning and in refrigeration, heat exchangers perform the essential task of providing a means for moving heat from one fluid to another. Danfoss MicroPlate heat exchangers (new product) for standard and for high pressure operation, whether copper or nickel brazed, are low fouling, highly corrosion resistant, hermetically sealed, and offer optimal heat transfer efficiency at low pressure drop. A broad array of standard designs is available, as well as custom designs for OEM customers

Comparison of the MicroPlate with traditional Brazed Plate Heat Exchangers

MPHE

Ultra Efficient Micro Plate (Dimple Pattern) NEW

BPHE

Traditional Plate (fishbone Design)

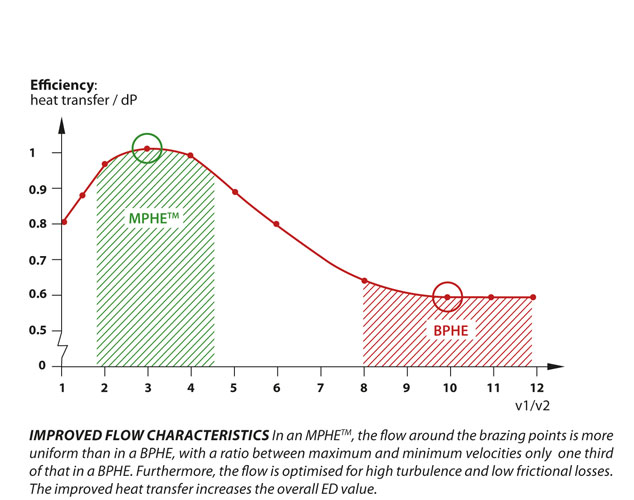

Improved Efficiency & flow characteristics

In an MPHE, the flow around the brazing points is more uniform than in a BPHE, with a ratio between maximum and minimum velocities only one third of that in a BPHE.

Furthermore, the flow is optimised for high turbulence and low frictional losses.

The improved heat transfer increases the overall ED value.

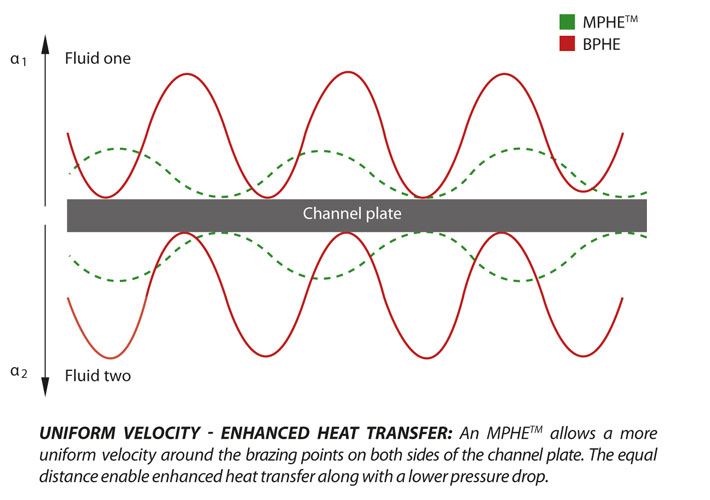

Uniform velocity – ENHANCE D HEA T TRANSFER:

An MPHE allows a more uniform velocity around the brazing points on both sides of the channel plate. The equal distance enable enhanced heat transfer along with a lower pressure drop.

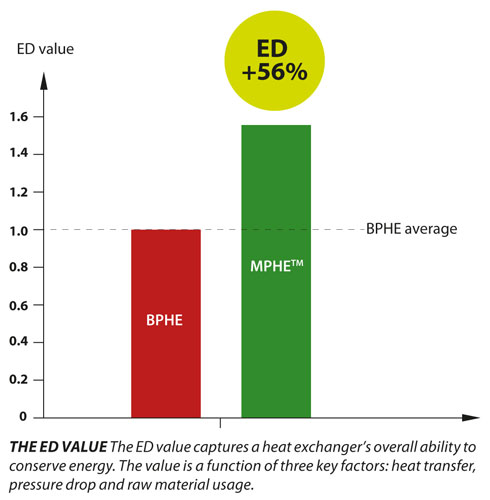

The ED value

The ED value captures a heat exchanger’s overall ability to

conserve energy. The value is a function of three key factors: heat transfer,

pressure drop and raw material usage.

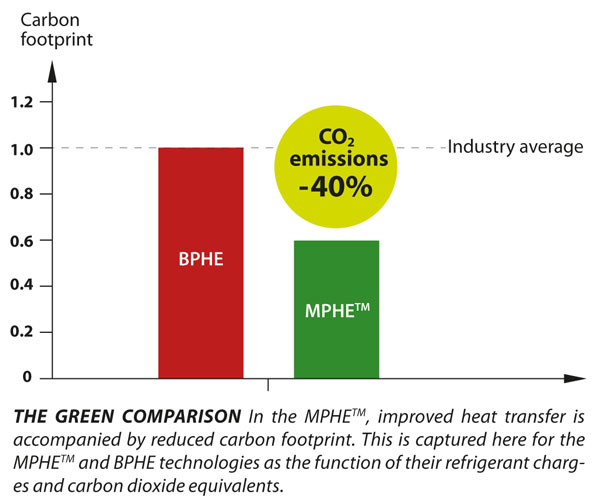

The Greener Solution

We bring you greener solutions with smaller CO2 footprints overall.

Compared with a chevron-type BPHE, an MPHETM has a 40% smaller CO2 footprint. The MPHE’s smaller hold up volume also means a lower refrigerant charge, saving money and further contributing to a reduced CO2 footprint.

Copyright 2009 – 2017 Techno Service Co. | All Rights Reserved | Powered by KaramiArt